Battery Testing Services to Improve Safety and Performance

Whether a plug-in hybrid or a fully fledged electric vehicle, automotive manufacturers are challenged to find alternatives to the conventional combustion engine.

They must be powerful, reliable, and safe. Critical features include interference-free interaction with the on-board electronics, resistance to environmental influences such as humidity, salt, and extreme temperatures, and resistance to vibrations and knocks.

In the rapidly evolving world of electric vehicles, XEFRA provides battery testing services. We ensure that batteries meet the highest standards of power, reliability, and safety.

XEFRA’s Battery Testing Capabilities

We provide battery certification services, ensuring batteries comply with international safety and performance standards.

XEFRA is able to perform:

- Environmental Resistance Testing: Employing temperature and climate cabinets with electrical operation, we test batteries against environmental factors.

- Vibration Resistance Evaluation: Through electrodynamic vibration systems, we assess the battery’s durability against physical shocks and vibrations.

- Electromagnetic Compatibility (EMC) Measurements: Utilizing shielded cabins and absorber halls, we ensure batteries maintain interference-free operation with onboard electronics.

- Corrosion Resistance Assessment: Salt fog chests and corrosive gas testing systems evaluate the battery’s resilience to corrosive environments.

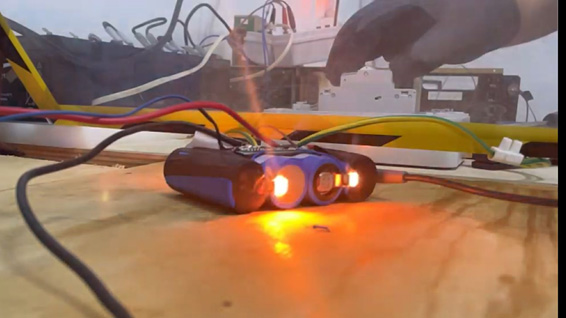

- Electrical Safety Tests: Covering scenarios like overcharge, overdischarge, and short circuit to ensure operational safety.

- Comprehensive test-specific security technology.

- Temperature control systems: simulating the internal cooling circuit.

- Leak Tests: Measuring equipment for leak testing.

- Tests for the reliability of electric vehicles: Ensuring the primary safety and functional safety of Battery Management Systems (BMS).